In a complete

drilling rig system, there is a solids control system which is used for

separate out the drilling cuttings from the drilling liquid which comes back

from the drilling wellhead. And with this solids control system, the drilling

cuttings are to the most separated out from the liquid, and after adding some

necessary chemicals into the clean liquid, the drilling mud goes back to the drilling

system. It is considered as a closed loop of drilling.

But you may ask,

how to deal with the drilling cuttings discharged from the shale shaker, mud

cleaner, desander, desilter and the centrifuge? Will the drilling cuttings

damage the soil or land of the environment?

And what to do

with the drilling liquid after it serves for several drilling rigs? Is it

possible that all the drilling cuttings are fully separated out? Is it possible

there are smaller and finer particles in the liquid?

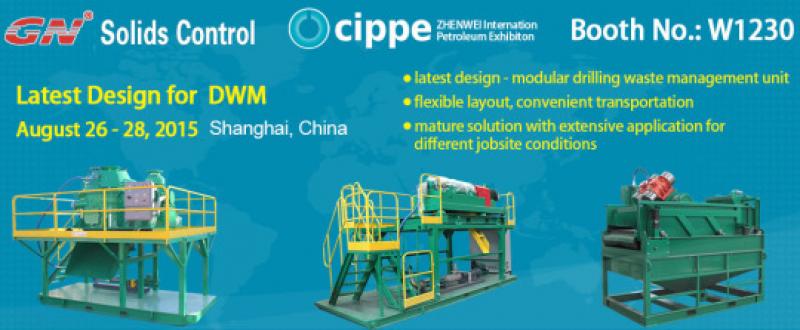

GN has answers

for those questions by using the waste management systems.

According to

their different function, the waste management could be divided as below:

1. the waste management

for further treating the drilling cuttings from the upper hand solids control

system. GN has several standard designed options for these waste management

systems. Normally, a screw conveyor collects and transfer the drilling cuttings

to the vertical cuttings dryer, the liquid discharged by the cuttings dryer

flows into a conserve tank of something alike to be transferred to decanter centrifuge

with a high speed. Both the solids discharged from the cuttings dryer and the

centrifuge are very dry. And liquid could enter to solids control system.

3. for the

drilling fluids, GN provide dewatering unit and high speed decanter centrifuge,

after some time operation, the particles become extra fine in the liquid, need

some chemical to merge them to be big enough for centrifuge separation.