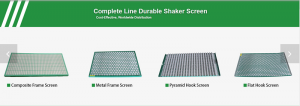

GN Solids Control will exhibit in the show as the leading manufacturer for the solid control equipment and waste management system. The booth number is E13A with the area of 15 square meters. GN will show its mini decanter centrifuge-223 and some high quality shale shaker screens at the show. GN’s 223 decanter centrifuge is specially designed for mining or piling industry. There are many great features for the equipment: the bowl material is made of duplex stainless steel 2205. The discharge port is protected by special carbide tungsten tiles which is with longer life and needed for less maintenance. The adjustable effluent port makes the pond depth change easier and more convenient. The pneumatic controlled spring will make the opening of the cover more easily and safely. The bearings are made by the world famous SKF company. The conveyor surface is made from Tungsten carbide tiles which is more endurable and easy for maintenance. This is really an eye catching product and GN believes that it will attract more and more attention from the show. Now GN’s second facility has been into production and increase the manufacturing capability a lot for shaker screens, especially for the composite framed screens, such as the replacement screens for MONGOOSE, KING COBRA, VENOM and so on. The composite frame represents the future trend of the industry due to its light and more endurable.