Recently we shipped one set of dewatering centrifuge with chemical dosing system to Singapore for TBM project. They bought one set of TBM desander unit model number GNMS-1000D before, which is our economic configuration mud cleaning unit for TBM slurry.

The technical specs are as below: Double deck shale shaker with 2 ea of 10 inch desander unit installed on a compact size mud tank with stairs, centrifugal pump feed the slurry to desander cone.

The working process is as below: the submersible slurry pump transfer the slurry to bottom shale shaker to separate coarse solids from the slurry, the fluids dropped into the mud tank, the centrifugal pump feed the clean fluids to desander cone, the clean fluids discharged from outlet pipe and flow to storage tank for reuse or further treatment. The separation cut point is 45 microns. The discharged solids dropped down to top layer shaker screen to recycle more useful fluids.

The dewatering decanter centrifuge model number is GNLW553-VFD,the bowl diameter is 550mm, the bowl length is 1800mm, the max capacity is 500gpm, and typical capacity is 400gpm, when adding flocculants, the treating capacity will be smaller based on different materials. The main motor is 90KW, the back drive motor is 37KW, the differential speed is 0 ~ 45 rpm, gearbox torque is 12000 N.m., the typical speed is 0 ~2500 rpm, the typical G force is 0 ~1888G.

Since the slurry desander unit separation cut point is 45 microns, it can not be reused directly, the dewatering centrifuge with flocculants can separate fine solids from the slurry up to 1 microns, the recovery water is clean and can be reused for TBM project to save cost for the client. The discharged solids with less moisture can be collected by bag and ship out by truck conveniently.

Month: April 2020

Oil Sludge Treating System for Domestic Client

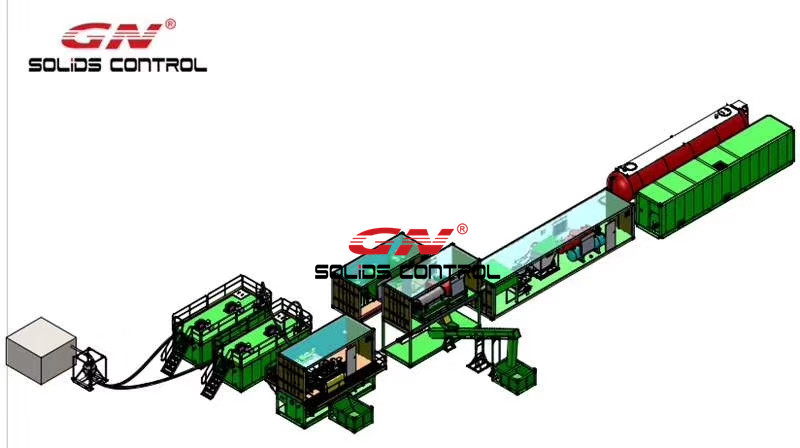

One unit of oil sludge treatment system for China client is shipped out recently, the design treating capacity is 15m3/h. A complete 15m3/h oil sludge treatment system made by GN solids control including vacuum pump unit, pre-mixing tank modular, shale shaker modular, chemical dosing unit, decanter centrifuge and 3 phase separation centrifuge modular. According to different material, we can provide customized design to add or remove the modular. The compact design in modular is for convenient operation and transportation.

- Vacuum pump is widely used to transfer waste oil, oil tank bottom cleaning sludge, drilling cuttings, drilling fluids, soils, sand, it is 100% air operated pump without electricity power.

- The vacuum pump transfer the oil sludge to pre-mixing tank modular, which with heating pipeline inside the mud tank to heat the oil sludge up to 60 degree. With chemical jetting and heating process, the emulsified oil can be easily treated and remove from the solids.

For free oil sludge, it can be treated by shale shaker modular directly. - The shale shaker modular with sealing cover and internal spray system is to separate the coarse solids from the oil sludge and reduce the solids content, it will protect the decanter centrifuge in the next step and extend the working life of the centrifuge screw propeller. If the solids content is too high, the screw propeller will be easily damaged; and the big solids will be easily block the centrifuge bowl.

- The decanter centrifuge can separate the fine solids from the oil sludge to reduce the solids content below 5%, by using proper demulsifier and chemicals, the separation cut point is up to 1 microns. The fluids treated by decanter centrifuge flow to the buffer tank then flow to the disc centrifuge, the disc centrifuge can separate oil, water and solids .

Mud recycling system case study for HDD & TBM projects

As a professional manufacturer of mud recycling system for HDD & CBM & TBM, our mud recycling system have been widely used for international big projects. Here are some typical projects case study:

Case study 1:

Project period: Year 2014 ~ 2019

Customer status: CHINA PETROLEUM PIPELINE BUREAU China-Russia gas pipeline Trenchless Project. CPP is the largest petroleum pipeline engineering company in China and the largest contractor for the China-Russia gas pipeline project. Over 20 units of GN mud recycling system are working for CPP projects. And 5 of these HDD mud recycling system are used in the China-Russia gas pipeline project.

Project status: The 3,000-kilometre (1,850-mile) pipeline, which was the world’s largest construction project ,will supply China with 38 billion cubic meters (1.3 trillion cubic feet) of gas annually when fully operational in 2025. Russian leader Vladimir Putin and Chinese counterpart Xi Jinping hailed the “Power of Siberia” pipeline as a symbol of cooperation.

Case Study 2:

Project period: Year 2016 ~ 2018

Customer status: Hong Kong Airport

Project status: HDD Trenchless mud cleaning and recycling for 5.2 KM Aviation fuel Pipeline installation. The mud recycling system specification including:

2 sets of 1500gpm mud recycling system, including 6 sets of GNZS703 Shale Shaker, 2 GNZJ703E-3S16N mud cleaner, 2 mud tanks, and centrifugal pumps and screw conveyor.

The working process of the mud cleaning system is : the submersible slurry pump feed the slurry to shale shaker, the coarse solids are separated out from shale shaker screens, the clean fluids dropped into shaker tank, the centrifugal pump feed the clean fluids to mud cleaner desander cone to separate solids bigger than 45 microns, the clean fluids dropped into desander compartment, the centrifugal pump 2 feed the clean fluids to desilter cone to separate solids bigger than 20 microns, the clean fluids are storage into the desilter tank.

Solids Control Centrifuge for drilling mud treatment to Russia

This week GN solids control shipped one batch of solids control centrifuges for drilling mud treatment to Russia.

The decanter centrifuge model is GNLW363CG, which is the best sold model and the most popular model. The technical specification is as below:

Bowl diameter: 360mm ( 14 inch)

Bowl length: 1270mm (50 inch)

Design capacity is 200gpm, the normal capacity for drilling mud treatment is 132 gpm. The max bowl speed is 3900 rpm, the typical bowl speed is 3200 rpm, max G force is 3063G, typical G force is 2062 G, the separation cut point is 2 ~5 microns, by adding flocculants, the separation cut point is up to 1 microns. The differential speed is 38 rpm for high speed decanter centrifuge, for variable frequency drive decanter centrifuge, the differential speed is 0~45 rpm. The gearbox ratio is 57:1, main motor power is 50 HP, the back drive motor power is 15HP, the matching pump motor power is 11HP. For different material conditions, the actual treating capacity will be various.

The universal features of GN decanter centrifuge:

1) The bowl assembly is made of duplex stainless steel 2205, which lasts longer than SS304 & SS316L , the other bowl components are made of stainless steel 316L.

2) The screw is made of stainless steel by centrifugal casting, the open impeller design increase the treating capacity and improve the performance.

3) The fluids distribution port and solids discharge port are all protected by tungdten carbide alloy and it is replaceable.

4) The screw propeller is protected by tungsten carbide tiles, which is abrasion resistance material , and once damaged, the tiles can be replaceable.

5) The bearings are SKF brand which can last long time.

6) The main motor, and back drive motor are installed in one side for convenient operation and compact design.