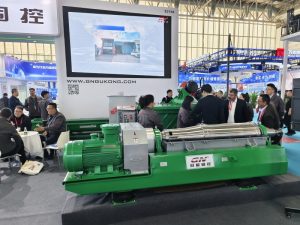

GN Solids participate in ITTC 2025 exhibition in China last week successfully. ITTC is an important exhibition for getting acquainted with new customers, meeting old friends, providing information on HDD industry trends, and sharing future technologies among international clients.

The exhibition information is as below:

Exhibition name: 28th International Trenchless Technology Conference 2025

Location: Suzhou International Expo Center

Exhibition time: April 23 to April 25, 2025

The Scope of exhibits including:

Trenchless equipments and technology: horizontal directional drilling rig, directional instrument and its ancillary equipment, drilling tools and mud materials, etc; Impact spears, ramming hammers, and their associated equipment; Pipe jacking machine and its ancillary equipment, drilling tools, and mud materials, etc; Underground pipeline repair equipment, cleaning equipment, etc; Pipeline replacement equipment and its ancillary equipment, etc; Underground pipeline detection instruments and equipment; Water supply and drainage pipelines, oil and gas pipelines, power and communication pipelines, and their anti-corrosion materials; Trenchless construction technology and its software, etc; Various auxiliary equipment such as trenchless pipe welding machines and lifting machines; Related trenchless equipment supporting production units, etc.

What products GN solids showed at ITTC 2025 exhibition?

1. TBM slurry separation plant GNTBM-360B, equipped with GNZS1536-2A (14KW) desander cleaner, the vibration amplitude is 4~8mm, the deck angle is adjustable from -3 °~ +3 °. The upper deck screen area is 5.4m2, and lower deck screen area is 5.4m2, with 2ea of 16 inches desander cone and 8pcs of 6 inch desilter cone, and the separation cut point is 30 μm.

2. Dewatering centrifuge: GNLW632B

As one of the trenchless equipments and system manufacturer in China, GN solids control can produce HDD & CBM mud recycling system, TBM slurry separation plant, Pilings desander unit and other drilling mud cleaning system. Such as shale shaker, desander, desilter, mud cleaner, dewatering centrifuge, chemical dosing unit,etc.