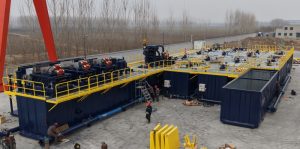

Recently one complete set of module Hydrovac slurry dewatering system are ready for delivery.

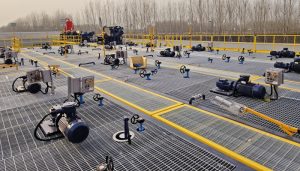

There are totally five modules for the customized hydrovac slurry dewatering system:

Coarse screening module: GNLMP-1536 mining coarse separation screen is used to remove coarse solids from the construction slurry. The high screening efficiency and large treating capacity can ensure the further step treatment with better performance.

Fine screening module: Double deck fine screening shale shaker GNZS596K can separate fine solids from the construction slurry. The top layer screen work as coarse solids separation screen, the bottom layer screen works as fine solids separation screen, the max treating capacity is up to 140m3/h, compared with the single deck shale shaker, the double deck shale shaker can remove the fine solids better, and make the discharged solids drier.

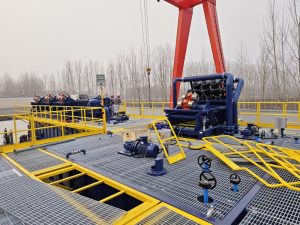

Desanding & desiltering module: The mud cleaner is a combination of desander cone, desilter cone and bottom shale shaker. The desander cone separation cut point is 40 microns, the desilter cone separation cut point is 25 microns.

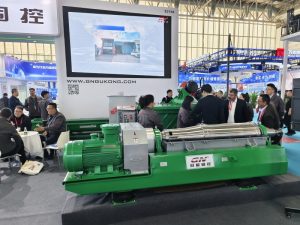

Centrifuge separation unit: The big bowl big volume decanter centrifuge GNLW553D-VFD is used to separate the ultra fine solids 5~10 microns by working with chemical doing unit, the mixed chemicals is prepared and transferred by the chemical dosing pump to static mixer, the fluids is feed by the feeding pump to the centrifuge feed tube, the chemicals adding is to increase the centrifuge separation performance and to make the discharged solids drier, which will be collected by waste collection box.

Chemical dosing unit: the 20ft containerized chemical dosing unit, including fully automatic polymer mixing, storage and injection to enhance dewatering. The container type chemical dosing unit is designed for convenient transportation, operation and for better protection.

For more information about GN modular hydrovac slurry dewatering system, pls contact with GN solids control.