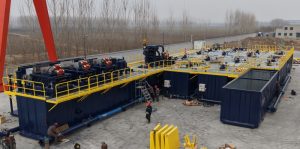

Recently one set of 3000HP drilling rig solids control system are ready for delivery to Asia drilling company. As one of the top solids control system manufacturer in China, GN Solids Control can produce comprehensive line of standars solids control equipments and customized mud tank system for international drilling companies.

The technical configuration is as below:

1. Trip tank 80bbl with liquid level meter, mud agitator, trip pump and pipelines

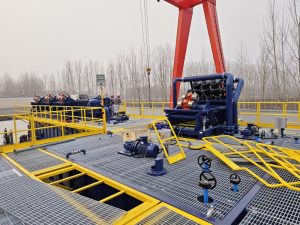

2. Shaker tank with triple shaker skid and possum belly, vacuum degasser, mud agitator, mud gun, desander feeding pump and desilter feeding pump, the shale shaker model is GNZS596K double deck shale shaker with 6 panel screen, each screen size is 585x1165mm composite material frame shaker screen, drived by 2ea 2.6HP vibration motor comply with ATEX zone 1 application.

3. Intermediate tank with mud cleaner, mud agitator, mud gun, the solids control decanter centrifuge and feeding pump with be provided by the client.

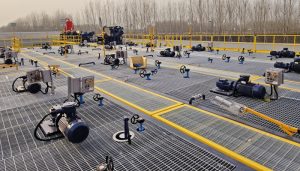

4. Suction tank 500bbl including mixing tank, suction tank, slug tank with mud agitator, mud gun

5. 4 sets of 500bbl reserve tank with mud agitator, mud gun

6. 2 sets of Water tank with water pump ,

7. Top open water tank

8. Pipelines provision of suction of mud from any of the reserve tanks with any of the mud pumps and with suitable facilities for transfer of mud from active to reserve tank or vice versa. Also, suction from intermediate tanks to mud pumps to be possible.

9. Separate pre-flush tank

10. Mixing hopper skid, including 3 sets of mixing pump, 2 sets of venturi hopper, 1 unit of shearing unit, with pipelines, control panel, accessories on one skid.

11. ATEX explosion proof electric control system

12. Walkways, guardrail, stairs

If you need a customized drilling rig solids control system, pls contact with GN solids.