Recently 2 sets of HDD mud cleaning system are ready for shipment to Sinopec. The first one is 240m3/h (1000GPM) HDD mud cleaning system, the second one is 120m3/h (500GPM) HDD mud cleaning system.

240m3/h (1000GPM) HDD mud cleaning system

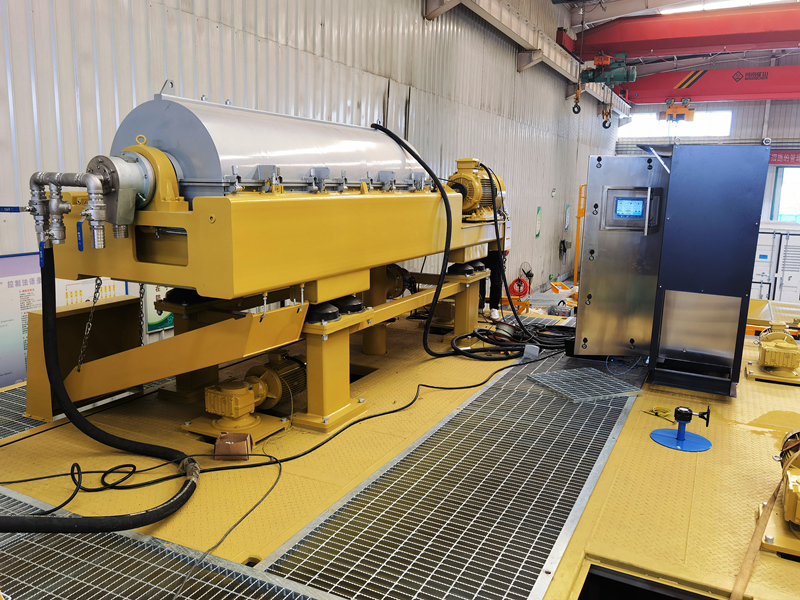

Including 2 sets of GNZS703F shale shaker, 1 set of GNZJ70F-2S12N mud cleaner with 2 units of centrifugal pump as desander, desilter feeding pump, 1 unit of big bowl big volume dewatering centrifuge GNLW554EP-VFD, jet mixing unit 1 unit, mud tank 4 units. The shale shaker is the first phase cleaning equipment to separate the coarse solids from HDD drilling mud, the mud cleaner with desander cone, desilter cone and bottom shale shaker, the desander cone is the second phase cleaning equipment to separate solids cut point 45~75 microns, the desilter cone is the third phase cleaning equipment to separate solids cut point 25~45 microns. The big bowl dewatering centrifuge mechanical separation cut point is 2~5 microns, GNLW554EP-VFD with bowl diameter 22 inch, bowl length 91 inch, the designed max treating capacity is 600gpm, typical treating capacity is 480gpm, max G force is 3051G, the typical G force is 2412G, with proper chemical dosing system, most of the ultra fine solids can be separated out. After long time operation, many fine solids will accumulated in the HDD drilling mud, the used drilling fluids treated by desilter cone can not be reused to prepare for new drilling fluids, the dewatering centrifuge should be used to separate ultra fine solids.

120m3/h (500GPM) HDD mud cleaning system

Including 1 set of GNZS703F shale shaker, 1 set of GNZS70F-1S8N mud cleaner with 2 units of centrifugal pump as desander, desilter feeding pump, 1 unit of dewatering centrifuge GNLW452D, jet mixing unit 1 unit, mud tank 2 units.

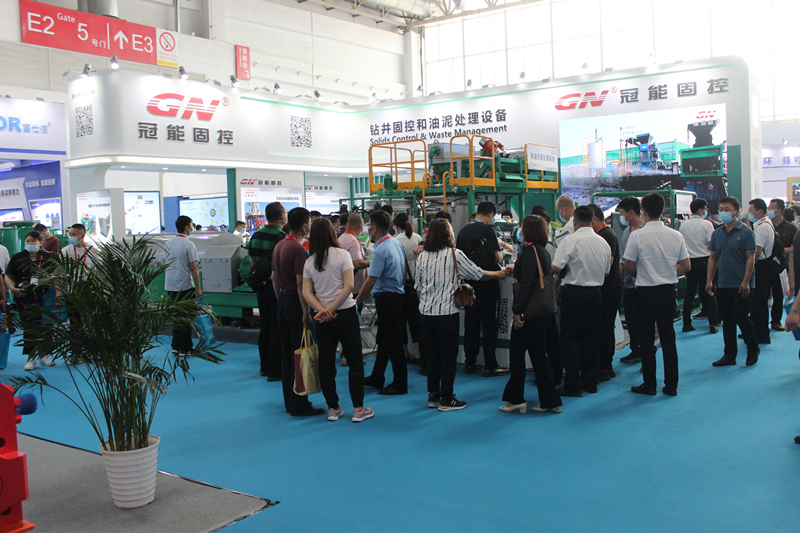

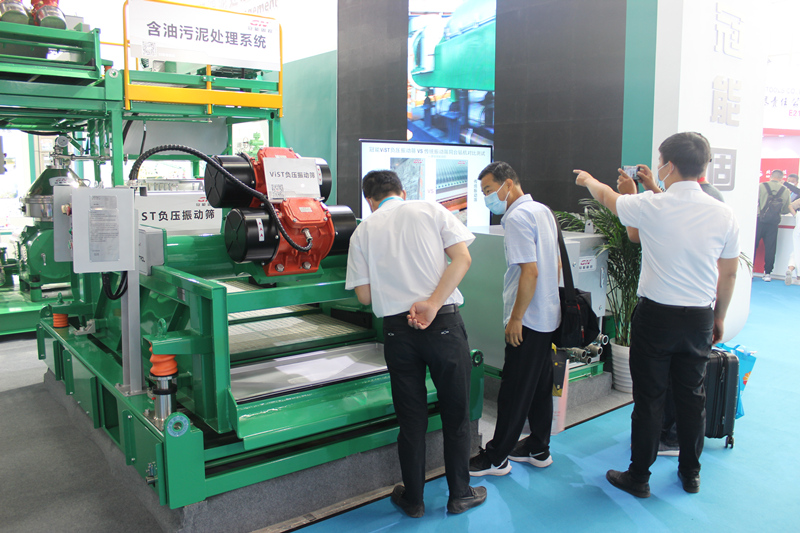

If you need customized HDD mud cleaning system, pls contact with GN solids control.