Recently GN solids control shipped one set of drilling cuttings solidification unit to our client in Africa. The cuttings solidification unit is widely used for water based cutings final disposal. The technical specification of GN drilling cutting solidification unit:

1) GN stand drilling cutting solidification unit is mounted on 2 skid, one is solidification mixing unit, one is cuttings storage hopper skid. During transportation, the solidification unit is loaded into 40ft container, and the 2 separate skid for convenient operation.

2) The cuttings storage hopper skid including waste collection hopper and accessories and screw conveyor , the user can damp the cuttings waste into the collection hopper, the screw conveyor transfer the waste to solidification mixing unit continuously.

3) The solidification unit including lime storage box, absorber storage box, high shear mixer, all of these components are installed on one skid. The screw conveyor dropped the cuttings into the vessel, at the same time, the lime and absorber are transferred by separate augers, all of these materials are mixed into the vessel, and transferred by the inner screw to solids discharged port. If chemical is necessary, it can be add through the liquid inlet .

Before feeding the GN solidification unit, to save the operation and material cost, the drilling cutting should be as dry as possible. The client can use water based drilling waste management system before feeding to cuttings solidification unit.

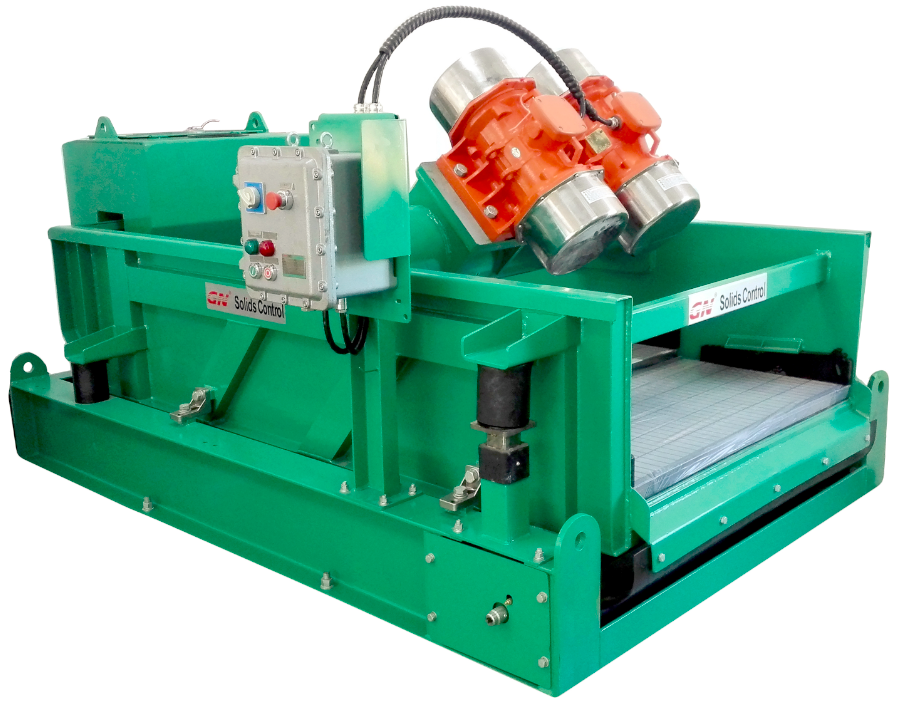

Normally we use high G drying shaker and high speed decanter centrifuge package. The screw conveyor collect the water based drilling cuttings and transferred to high G drying shaker, the coarse solids are separated out, the fluids dropped into the buffer tank, the screw pump transfer the liquid to VFD decanter centrifuge, then the fine solids are separated out, the fluids are flow to solids control system for reuse, the cuttings are collected by trash box and feed to solidification unit.