Centrifugal pump is most important conveying device in a oil and gas drilling mud solids control system. Main structure and parts of centrifugal pumps are impeller, pump cover, guide wheel, shaft, bearing, sealing devices and etc.

- Impeller: impeller is the most important part of centrifugal pump, it transfers the generator’s energy to the liquid. Most centrifugal pumps’ impellers are made of iron.

- Pump cover: pump cover is used to guide the liquid flow from impeller, as the flow cut is gradually larger and larger, the liquid flow’s speed smoothly lowered. Then dynamic energy turns into pressure. Besides that, pump cover guides the liquid to outlet pipe.

- Guide wheel: guide wheel is installed on out edge of impeller and fixed on pump cover, its main function same as pump cover.

- Sealing devices. In order to make sure the efficiency of centrifugal pump, there should be insulation from inside liquid and outside air. GNSB centrifugal pumps use mechanical sealing for better performance.

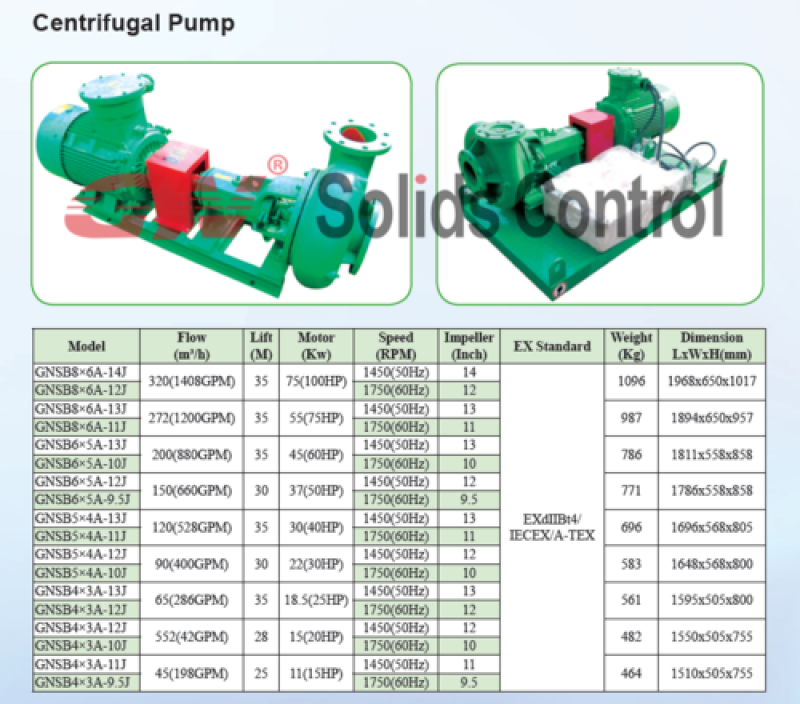

GNSB Series centrifugal pumps are one of main equipments GN Solids Control produce. In near future, GN will arrange a separate workshop especially for centrifugal pump production. GN centrifugal pumps’ spare parts are interchangeable with some world famous centrifugal pump. Each year, GN sells tens of systems with hundreds of centrifugal pumps. Besides that, GN also sells such pumps separately.

May you need such centrifugal pumps or pumps spare parts, pls contact me freely at renee@gnsolidcontrol.com