Recently GN drilling mud decanter centrifuge and centrifugal pumps are shipping to offshore drilling company.

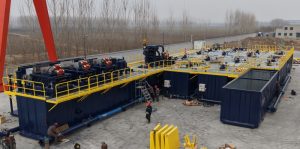

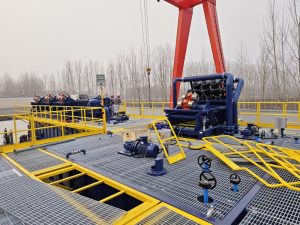

The drilling mud decanter centrifuge is equipped with offshore lifting skid, compared with the onshore drilling mud decanter centrifuge, the skid for offshore drilling is special designed for safety and convenient lifting for offshore purpose, but without DNV 2.7-1 lifting certificate. When DNV 2.7-1 lifting certificate for the lifting pad is required, the skid should be designed specially. The stainless steel cabinet positive pressurized VFD control panel is separately on the ground, with main motor, back drive motor and pump motor 3 VFD, which is from ABB, YASKAWA, etc. famous brand, the other like PLC and touch screen and other electrical conponents from Siemens and other famous brands. The decanter centrifuge bowl and the screw core shaft are made of duplex stainless steel SS2304 by centrifugal casting, which is superior to the performance of SS304 and SS316.The solids outlet and fluids distribution port is protected by replaceable hard alloy sleeve. The wear resistant and anti-skid bars welded inside the bowl can effectively reduce the wear of the bowl under operation. The screw main material is also duplex stainless steel 2304. The screw blade is protected by tungsten carbide tiles, which is replaceable hard alloy plate.

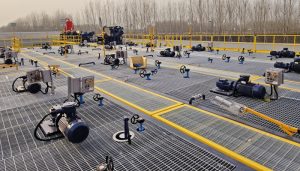

The centrifugal pump all the parts are interchangeable with international brand pump, so the client can source the parts easily. The pump casing made from hard ductile iron alloy, which increased abrasion resistant performance. The pump skid is special designed for client’s particular requirement.

Except for drilling mud decanter centrifuge and centrifugal pump, we also produce linear motion shale shaker, mud cleaner, desander, desilter, vacuum degasser, mud agitator, mud tank system, etc. solids control equipments for the onshore and offshore drilling. For more information, pls contact with GN solids control.