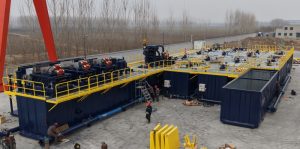

Recently one set of 500 gpm mud recycling system for trenchless mud treatment and one set of diamond core drilling hydraulic drive solids removal unit for overseas client.

The 500 gpm mud recycling system consists of shale shaker, mud cleaner, desander feeding pump, desilter feeding pump, 20ft container size mud tank, 20ft container lifting frame, mud tank accessories and electric control system. It is a customized design 500gpm mud recycling system for our client, we also have standard 200gpm, 400gpm. 600gpm, 800gpm, 1000gpm mud recycling system for HDD mud cleaning, mixing, recycling.

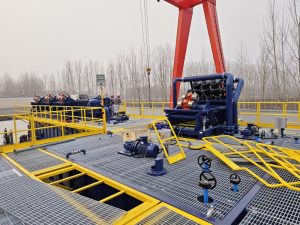

The core drilling hydraulic centrifuge system is solids liquid separation of waste water for diamond core drilling. The features of the core drilling hydraulic centrifuge system including compact design, modular design, lightweight to meet the requirement for helicopter hoisting, can operate without electricity power supply. The technical configuration is as below:

1. GNLW223D-FHD hydraulic centrifuge

2. Feeding and discharge pump: 2X FHD pump

3. Treating capacity: 50~130L/Min

4. Separation cut point: 2~5 Microns

5. Driving method:Diesel + Hydraulic drive

6. Mud tank volume: 2m3

7. Total power consumption: 40KW

8. Mixing hopper

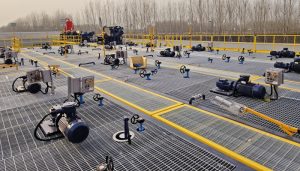

The treatment process is as below:

The mud is pumped into the sedimentation bin of the buffer tank, so that the large particle sedimentation. After that, the mud overflow to the slurry supply bin of the feeding tank, the pumped by the #1 slurry pump to the hydraulic centrifuge for ultrafine solids separation. If without the sedimentation process, one unit of mini shale shaker will be used to separate the coarse solids from the mud. The mud treated by the hydraulic centrifuge flows into discharge tank and transferred to drilling machine by No.2 transfer pump, the treated clean water can be reused to prepare for new drilling fluids and used by the core drilling for cost saving.