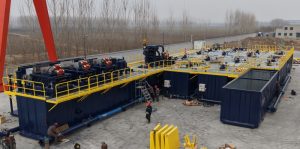

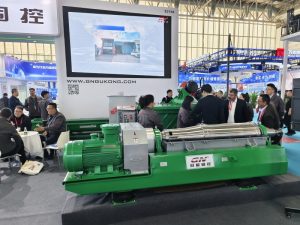

Last week GN solids control finished CIPPE 2025 exhibition in Beijing successfully. As a manufacturer of drilling fluid solids control and drilling waste management solutions, showcased its innovative technologies at CIPPE 2025 in Beijing. The exhibition CIPPE , one of the largest oil and gas exhibitions in Asia, provided an excellent platform for manufacturers and users to highlight its advanced shale shakers, decanter centrifuges, and drilling waste management systems.

The exhibition details is as below:

Exhibition Name: The 25th China International Petroleum & Petrochemical Technology and Equipment Exhibition

Exhibition date:March 26-28,2025

Exhibition location:Beijing, New China International Exhibition Center

GN Stand number:E2168

Key Highlights of GN’s Exhibition at CIPPE 2025:

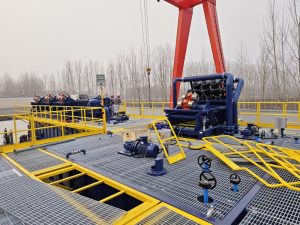

1. Lastest Generation Shale Shakers – double deck shale shaker with 6 panel 585×1165 mm shaker screens, last panel with collection pan of vacuum unit for future installation of vacuum screen unit conveniently, top screen as coarse solids separation, the bottom screen as fine solids separation.

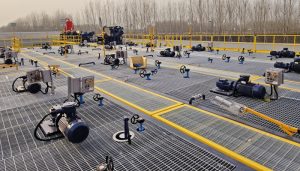

2. Fully Hydraulic drive Decanter Centrifuges –Viscotherm and ROTODIFF® from Switzerland for centrifuge hydraulic driving system, it is special to use in high temperature ambient for heavy mud with flexible bowl and differential speed. The compact design makes it easier for rig up.

3. Big bowl big volume decanter centrifuge- for big volume treatment requirement TBM and Piling project, Mining tiling separation.

4. Sludge vacuum pump – 100% air operated pump, no need electricity power, suitable for hazardous area application. The suction distance is up to 50m, discharge distance up to 500 ~1000m , the transfer solids size maximum 50mm or 75mm, sludge solids content up to 80%

GN Solids Control continues to push the boundaries of solid control technology, helping clients achieve higher productivity, regulatory compliance, and sustainability. Take this chance of CIPPE 2025 to explore how GN’s solutions can revolutionize your operations.