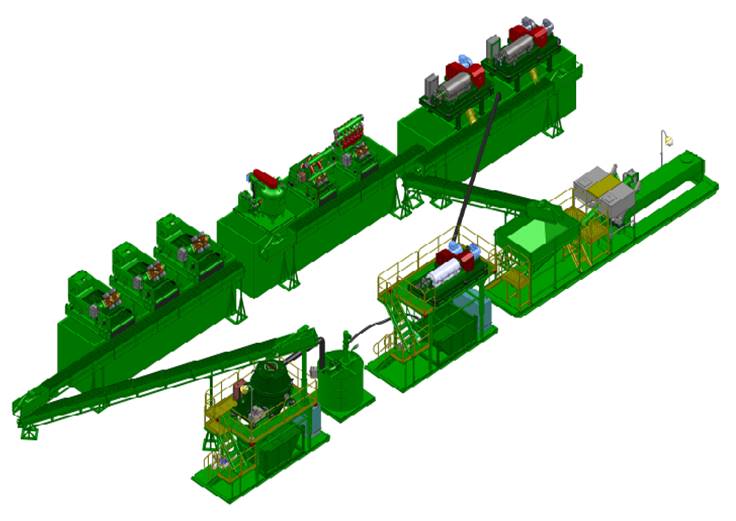

According to the required treating capacity and maximum density/ viscosity of the drilling fluids, the user can select different numbers of high performance linear motion shale shakers. For example, normally 1000gpm treating capacity at 15cP will select 3 units shale shaker, 2 units in operation and 1 unit as back up. Sometimes as per client’s requirements, they can use 2 units of shale shakers, we have 3 panel linear motion shale shaker, 4 panel shale shaker ( linear motion, dual motion for option) for selection. E.g. when required treating capacity is 1200gpm at the same viscosity, they may also use 3 units of solids control shale shakers, single layer, 3 or 4 panels shaker screens, linear motion or dual motion as per required.

We can produce tandem shale shaker to install 2 units shale shaker on one skid with possum belly and pipelines, also we can produce triple shale shaker to install 3 units shale shaker on one skid with possum belly and pipelines, valves, arrangements. The package design is for easy transportation, easy operation.

Solids control shale shaker is the equipment to separate the solids based on physical size, which is decided by the shaker screen mesh size (the screen opening size ). The further phase separation equipments, such as desander cone, desilter cone, decanter centrifuge, separated based on the difference between fluids and relative weight.

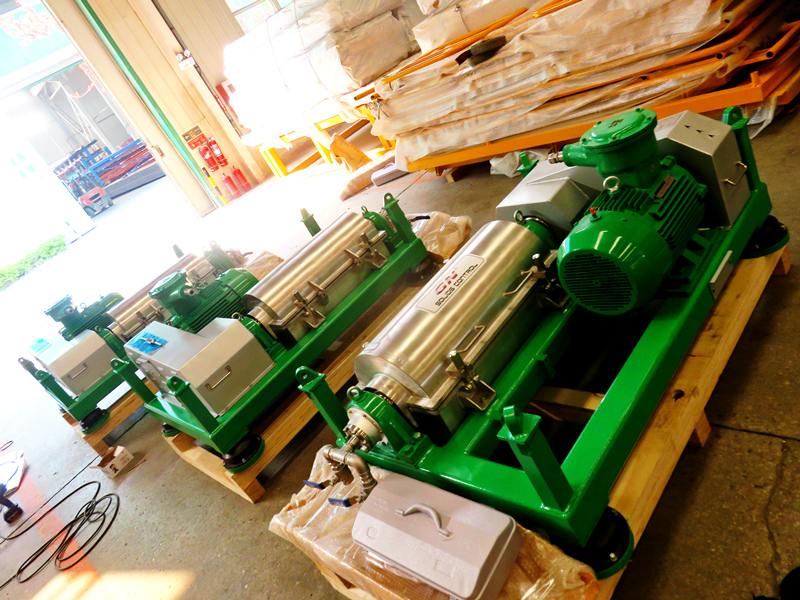

GN designed shale shaker are all installed with composite material frame shaker screens, the dimension is different based on different models. Except for single layer shale shaker, we also produce double deck shale shaker when required treating capacity is very high. Right now GN solids control have one batch of solids control shale shakers in stock for sale, if you need high performance linear motion shale shaker urgently, pls contact with GN Solids.