Recently one batch of drilling fluids shale shaker and mud tank are shipped for offshore drilling companies. This is repeat order from our client.

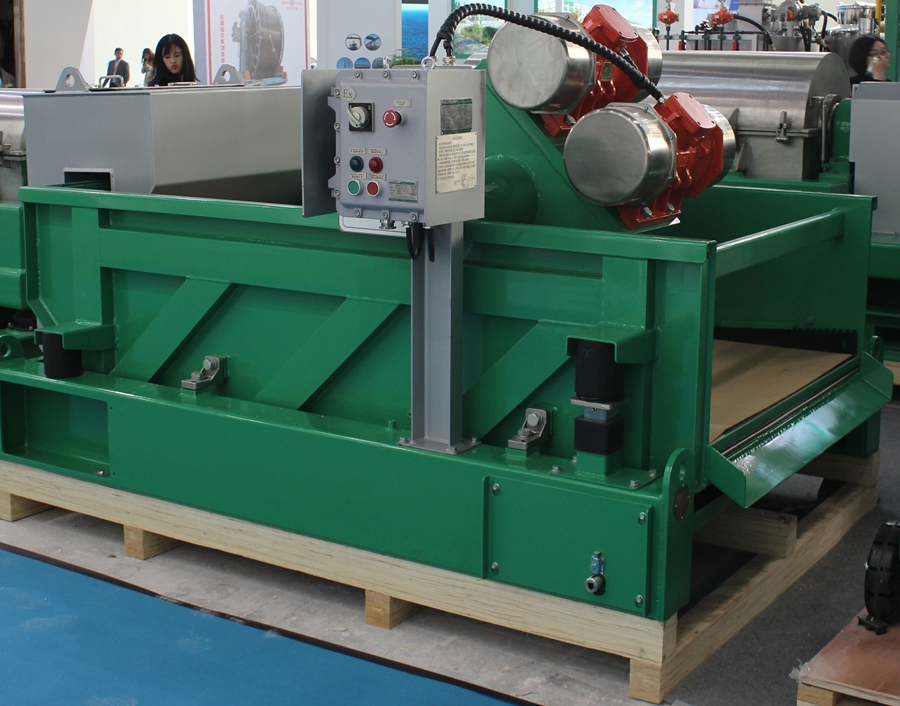

The shale shaker used for offshore drilling companies are with ATEX explosion proof (or comply with marine used motor and control panel) vibration motor and control panel. The coating and painting is PPG Protective & Marine Coatings, 3 layers, 1st layer is Zinc rich Heavy Duty epoxy primer, 2nd layer is Epoxy micaceous iron oxide intermediate, 3rd layer is polyurethane topcoat finishing. The shaker screen used is composite material frame pre-tensioned shaker screens for longer working life. The shaker deck angle can be adjusted by ratchet wrench from -1° to +5°. The screw lifting device can be adjusted at the same time from both sides.

The mud tanks for offshore drilling consists of skid mounted centrifugal pump with lifting frame, mud tank with mixing hopper, pipelines, lightings, guardrails, walkway, stair, etc. The shale shaker will be installed on top of mud tank. All the mud tank and other modular is installed with lifting pad or lifting frame for convenient movement.

Except for shale shaker and mud tank, GN solids control also produce mud cleaner, desander, desilter, vacuum degasser, centrifugal pump, mud agitator, mud gun, mixing hopper, shaker screen, decanter centrifuge, mud gas separator, vertical cuttings dryer, screw conveyor, etc, which can be used for both onshore and offshore drilling with different standard.

Mud cleaner is a combination of desander cone, desilter cone and bottom shaker, the desander cone and desilter cone are all made of 100% polyurethane material for better wear resistant, by using different qty hydrocyclones, we can provide different treating capacity mud cleaner. The bottom shale shaker model can be used as back up shale shaker when it is required. if you need more information of offshore drilling shale shakers, pls contact with GN.