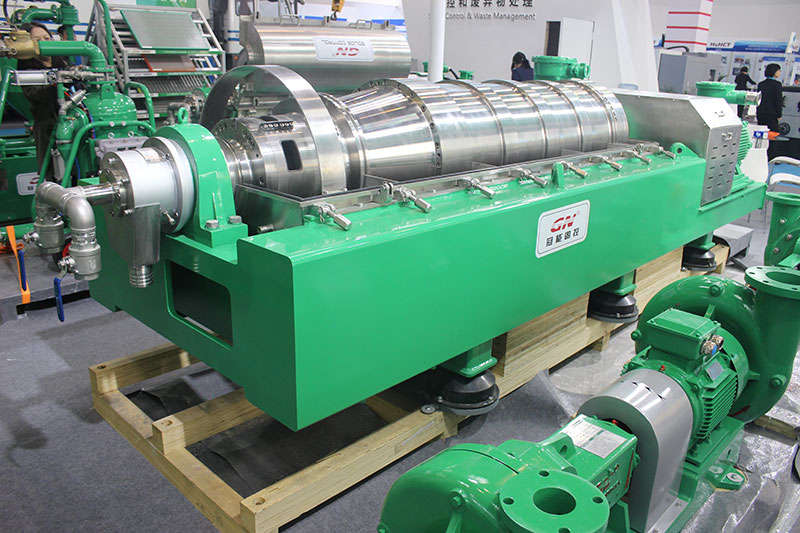

Recently GN solids control shipped 10 units of VFD decanter centrifuges to Middle east with IEC explosion proof motor and VFD control panel, these are high configuration decanter centrifuge, which can be widely used for dewatering unit, drilling fluids treatment, drilling cuttings treatment, waste water treatment, oil sludge separation system and all other kinds of liquids and solids separation.

The decanter centrifuge package including screw pump, telescopic skid, decanter centrifuge and VFD control panel, all in one skid for convenient transportation and operation.

Features of GN VFD control panel:

1) Positive pressurized VFD control panel with PLC smart control, with self cooling system and HMI interface, 3 motors VFD for main motor, back drive motor and feeding pump motor.

2) The motor and control panel is IEC EX certified for zone 1 application, suitable for operation temperature -20-55℃, especially suitable for Middle East area.

3) The inverter is ABB brand, and all the electrical components are option for ABB/ Scheneider/ Siemens.

4) The VFD control cabinet is made of stainless steel material for longer working life and better corrosion resistance.

5) The cable gland, power supply pin and aviation plug are all IEC EX certified.

Features of GN decanter centrifuge mechanical part:

1) Bowl material is made of duplex stainless steel 2304 or SS2205, the other parts of bowl is made of SS316, the collection box is also made of stainless steel 304 for better corrosion resistance.

2) The screw is made of stainless steel material and heating treatment up to 1000 degree, the opening screw propeller increase the treating efficiency.

3) The bearing is SKF brand

4) The screw protection is tungsten carbide tiles and repairable, the solids discharge port and fluids distribution port are all protected by tungsten carbide alloy and it is interchangeable.

For more information, pls contact with GN solids control.