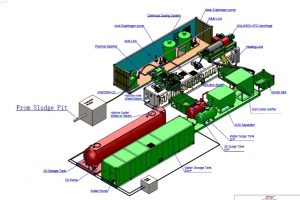

In recent weeks, GN Solids Control is busy assembling and completing the mud recycling system for an overseas customer for the 1500 HP drilling rig. This system is with full stages of solid control equipment and large liquid storage tanks. Since its establishment in 2007, GN has already started manufacturing the solid control equipment for the oil and gas industry. After 10 years development, GN has already accumulated much experience and can be customer’s one stop shop for solid control system. Now its product range spanning from shale shakers, mud cleaners, decanter centrifuge, cutting dryer, vacuum degasser and so on.

The mud recycling system is mainly composed of the following elements: there are 14 tanks in total used for mud recycling, storage and mixing and for water and fuel storage. There are 3 units of shale shakers which will be connected to the mud distributors that will distribute the drilling mud coming through the pipeline from the wellbore. There is also a mud gas separator to eliminate the flammable gas for safety purpose. And after the shale shaker, there is one vacuum degasser which will be used to remove the cut in gas in the mud to improve the efficiency of the centrifugal pump. After that is one mud cleaner which is composed of desander, desilter and underlying shale shaker. One decanter centrifuge is also equipped in the system for barite recovery. This can save the operator a lot of money as barite is very useful and expensive. There are also various pumps installed in the system to perform their function, such as the centrifugal pump which is used to transfer the drilling mud in the system. And there are also about 30 units of agitators and mud guns which will be used to clean the corners of the tank and mixing the mud in the tank to keep the mud property at good level.

That’s the brief introduction about the mud recycling system. Hopefully it will be useful to you. GN has many types of configuration for different mud recycling system for different HP drilling rigs. Welcome to visit www.gnsolidsamerica.com and please send your inquiries to sales@gnsolidscontrol.com