Mud cleaning system is critical in the drilling process as they protect the system components by lowering solid/sand content in the drilling fluid. Cleaner fluids means much longer and expandable life in the entire mud cleaning and pumping system. Lowering solid content also allows drilling fluid to carry the sand from the bore more efficiently, making for a better bore hold and improving the rate of penetration dramatically. And it can also solve the environmental and disposal issues and save a lot of cost.

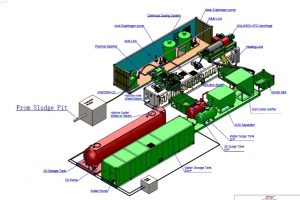

GN’s mud cleaning system are made on skid, like modular, which makes it very easy for transportation. The mud system mainly includes five components: shale shaker, shaker screens, hydrocyclones( desander, desilters), mud tanks, and electrical motor and centrifugal pump. GN’s shale shaker is mostly in linear motion and is used for the coarse separation. It mainly separate the solids by its size by the screen. For the screens, GN now can manufacture its OEM screen with GN brand, also it can manufacture some famous replacement screens, such as DERRICK, MI-SWACO and BRANDT. After the shale shaker, the mud will be pumped by the centrifugal pump into the hydrocyclone which uses centrifugal force to separate the solid from liquid. It can separate the solid size up to 20 microns. The mud tanks usually have 3 compartments, which will hold the mud coming from different separation stage. The size and capacity will depend on the drilling rig size and fluid flow rate. Now GN can manufacture and supply all the components with high quality and low cost.

That’s the brief introduction about the mud cleaning system. Hopefully it will be useful to you. GN has many more solid control systems, they can be used in different operational situations and help you achieve your target easily and cost effectively. Welcome to visit www.gnsolidsamerica.com and please send your inquiries to sales@gnsolidscontrol.com