GN Solids Control is an integrated company for manufacturing the solid control system and waste management equipment and system. Established in 2007 in China, GN now has grown from a local Chinese company to an international company with its products sold to more than 60 countries. In 2014, GN set up its overseas subsidiaries in US and Russia to get closer to the local customer and better serve the local market.

Among all the GN’s product line, there are there main ones which are more reliable, mature and popular in the market, they are shale shaker, decanter centrifuge and cutting dryer. As one of the key components in the solid control and waste management system, decanter centrifuge plays an important role in the solid and liquid separation process.

Among the Decanter centrifuge’s different specification and configurations, GNLW 363C is the most popular and reliable, it is the star product. There are fixed speed centrifuge and VFD controlled centrifuge. There are many highlights about the equipment: the bowl material is made from duplex stainless steel 2205 which is made by centrifugal casting, and it’s much better than stainless steel 304 and stainless steel 316. The solid waste discharge port is protected by special ceramic inserts which is made by world famous manufacturer with longer and more endurable life. The adjustable effluent port make the pond depth adjustment easier and more convenient and fast. The pneumatic controlled spring will make the opening of the cover more easily and safely. During the transportation, the bowl lifting bracket can perform as the protection for the bearings. The bearings are made by the world famous SKF company. The two motors are placed at one side of the equipment and make it smaller footprint. The conveyor surface is made from Tungsten carbide tiles which is more endurable and easy for maintenance. The VFD system is provided by ABB or SIEMENS. ATEX and IEC EX for zone 1 control panel can be provide as request.

We will try our best to assist your business to be successful. Welcome to visit www.gnsolidsamerica.com and please send your inquiries to USA@gnsolidscontrol.com

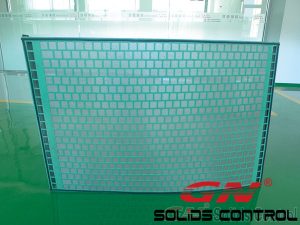

Shaker screens in stock for sale in GN’s US warehouse

GN Solids America facility was first established in 2014 in Houston, TX. The facility is a multi functional with office, assembly center and spare parts center. The facility takes about 30,000 square feet. This office is the first overseas subsidiary for GN Solids Control and is performing the function as sales, after market service and warehousing.

Now in GN Solids America warehouse, there is plenty of shaker screen in stock. There are many types of screen there, such as the GN own brand GNZS series, replacement screens for MI-SWACO MONGOOSE PRO, MONGOOSE PT and MEERKAT, ALS, BEM; replacement screens for DERRICK FLC 2000, FLC 500, DP 600, and hyperpool; replacement screens for NOV Brandt Cobra, King Cobra, Mini Cobra, Venom, LCM-2D, LCM-3D, VSM 300 series( include scalping, primary and secondary) and replacement screen for some other popular brand, such as Fluid System. GN Solids control can manufacture many types of screen, such as the composite frame, metal frame, soft hook strip and hard hook strip. The screen could be flat or pyramid according to customer’s requirement. The screen could be 2 layers or 3 layers depending on the customer’s requirement for the API number. The screen surface are made of stainless steel, usually use SS304 or SS316. This material can make the screen more endurable and work for longer time. GN can manufacture the screen from API 20 to API 400.

GN Solids Control’s 2nd manufacturing facility for shaker screen will soon be in production. It will be about to produce about 5000 pieces of screens annually. The screen frame will be mainly composite material. GN recommends our customer to use composite frame shaker screens because it’s lighter, has longer usage life, corrosion resistant and has larger non-blank area. Now GN screens have been sold to global market, we hope to get your inquiry soon.

Welcome to visit www.gnsolidsamerica.com and please send your inquiries to USA@gnsolidscontrol.com

Solids Control Equipment for Offshore Drilling

Solids control equipments are commonly used in property rig drilling project regarding drilling fluids recycling in addition to cleaning. Properly recycling the actual drilling fluids could appreciably reduce the cost on drilling fluids and the discharged number of waste cuttings. Offshore drilling also produces drilling cuttings and other waste material need to be dealt with. Among the material produced, typically the used drilling fluid could be the first one need to be disposed.

There are lots of places where the solids control equipment will be used, one of that is the devices used on offshore drilling cleaning system. A very compact flat which includes all the drilling machinery located firmly in the sea, while drilling, it will need the drilling cleaning system regarding treating the used drilling fluids. Due the restricted space on offshore program, the driller always take up the double or three times layers shale shaker as the principal separation on used drilling fluids. The mud cleanup system on offshore program includes all the necessary tools comparing with land computer, just working on the sea.

Just about all the offshore rig podium has enough mud aquariums for storage the drilling fluids. However , when there is above much ultra fine solids in the drilling fluids, the actual drilling fluids is not be capable of be used anymore if with virtually no further separation. At this time, this sort used drilling fluids should be transported to land to be treated. The barge ship can be used to transport this type drilling liquids from offshore rig software to the land and provide brand new and active drilling liquids for the rig. The burst ship need have quite a few mud storage tanks thus it can bring sufficient mud towards the offshore rig. The burst ship need also have often the mud mixing equipment with regard to mud mixing system on the deliver. The mud agitator and mud gun would also be needed for mud mixing system.

More consideration should be given to the market proof of the motor along with control cabinet, as it may well be more dangerous if there is a fire upon offshore rig or burst ship than on area rig. Thus, the electric powered components used for offshore needs to be strictly marin explosion evidence standard. The other thing ought to be given more attention is enough wear parts storage intended for offshore rig, as we acknowledged, it will be much difficult to the drilling to get a small don part once the equipment power down. That will be a waste regarding both time and funds.

GN Solids Control equipment in stock for sale in the US warehouse

GN solids America, the US subsidiary of GN Solids Control with Headquarter in China, was established in 2014 in Houston, TX. It is now performed as the manufacturing facility, warehouse and after sales service center. Now there are many kinds of products in the US warehouse for sale, such as the shale shakers, cutting dryer, decanter centrifuge, agitator, mud gun, centrifugal pump, and shaker screens. There are many kinds of screens that could be replaceable with many famous brands. And we also have both the steel frame screens and the composite frame screens. All the screens comply with API RP 13C.

Now there are 4 main equipment in stock, shale shaker, mud cleaner, cutting dryer and decanter centrifuge. For the shale shaker, the vibration mode is linear, the vibrator motor are made by famous Italy brand Oli which can guarantee strong power and great reliability. It can hold 4 pieces of screen. The deck angle range can be adjusted from -1 to 5 degrees(mechanical), the screen size is 585mm*1165mm.The vibration motor power is 1.94kw each. The mud cleaner is the combination of desander, desilter and shale shaker. The desander hydroclone size is 10 inch, the desitler hydroclone size is 4 inch. All the hydroclones are made of polyurethane, which is very endurable and light. This is also consumable, you may need to buy some for stock. We have plenty of hydroclones in stock now with competitive price. Welcome to inquire for that.

For the cutting dryer, the screen opening can be 0.25mm, 0.35mm and 0.5mm. The rotation speed can be like 900 RPM or 1200 RPM, and the G force could be reached to 420G or 750G. The cutting dryer are mostly in solids waste management, especially for oil based mud or synthetic based mud. For the decanter centrifuge, the bowl diameter is 14 inch and the length is 50 inch. The max capacity is 200 GPM and the effective capacity is 132 GPM. The max bowl speed is 3900RPM and the typical bowl speed is 3200 RPM. The bowl is made of duplex stainless steel 2205 by centrifugal casting, which is better than stainless steel 304 and stainless steel 316. The solids discharge port is protected special ceramic inserts which could last longer. GN solids control’s products are certified by API, ISO, CE, TP TC and are explosive proof with EX standard of IECEX and ATEX. With the reliable product, good service and competitive price, GN solid control will be your NO.1 choice in the solid control industry.

Welcome to visit www.gnsolidsamerica.com and please send your inquiries to USA@gnsolidscontrol.com

GN Solids Control and its main product line

GN solids control is a world famous manufacturer for solid control and waste management equipment and system. With the headquarter located in China, GN solids control has become a world famous brand that has been recognized by customers from more than 60 countries. And now it has grown from a local Chinese company to an international company which has established another two subsidiaries in the global energy centers, Houston,TX in the US and Moscow in Russia.

The solid control product range mainly covers the shale shaker, desander, desilter, mud cleaner, vacuum degaser, decanter centrifuge, mud gas separator, mud agitator, mud gun, jet mud mixer, flare igniter, and various pumps, such as centrifugal pump, shear pump, submersible pumps and screw pump. The waste management system equipment range mainly covers High-G shaker, cutting dryer, centrifuge and so on. Among all the equipment, there are 3 star ones which is most mature, most popular and most reliable. They are shale shaker, cutting dryer and decanter centrifuge. There are two kinds of shaker, one is used in the solid control for the oil and gas drilling, the other is called High-G shaker for the solid waste management. The shakers can separate the solids size over 60 microns. The decanter centrifuge and cutting dryer are both used for waste management, but centrifuge can also be used for solid control of oil and gas drilling. The cutting dryer has 3 kinds of screen size, 250, 350, 550 macrons. And the decanter centrifuge can separate solid size from 1-20 microns. GN solids control’s products are certified by API, ISO, CE, TP TC and are explosive proof with EX standard of IECEX and ATEX. With the reliable product, good service and competitive price, GN solid control will be your NO.1 choice in the solid control industry.

Welcome to visit www.gnsolidsamerica.com and please send your inquiries to USA@gnsolidscontrol.com