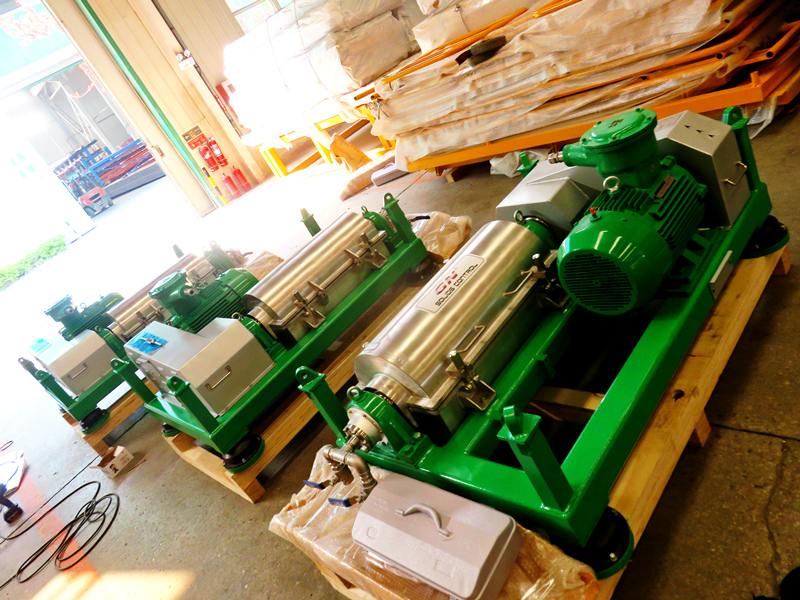

Portable decanter centrifuges are ready for shipment to core drilling company in Mexico. The mini centrifuge is attached with lifting pad on the four corners, the user can lift the portable decanter centrifuge easily to their work site, especially in some places where road transportation is limited. The technical specification is as below:

Model: GNLW223D

Centrifuge bowl diameter: 9 inch (220mm)

Centrifuge bowl length: 26.4inch (670mm)

Max bowl speed : 4500rpm

Typical bowl speed : 3800rpm

Max G force: 2492G

Typical G force: 1777G

Main motor: 11KW

Gearbox ratio: 35:1

Gearbox torque: 500N.M

The bowl material is made of duplex stainless steel 2205, the screw is made of SS316L, the screw propeller is protected by tungsten carbide tiles, the solids discharge port and fluids distribution port is protected by tungsten carbide alloy. The bearing is from SKF brand for reliable operation.

If the client need bigger treating capacity of fluids and cleaner treatment water, they can select GNLW224 series, which with longer centrifuge bowl length. Both of the GNLW223 and GNLW224 series mini decanter centrifuge are widely used for diamond core drilling mud cleaning unit, the purpose is to clean the mud, recycle the water and reused for drilling. When it is required to reduce the start electric current, VFD control panel will be installed on the skid, the VFD decanter centrifuge can be used in high altitude mountain.

GN mini decanter centrifuge is the main equipment for diamond core drilling solids removal unit, which consist of shale shaker, picking up pump, decanter centrifuge, centrifugal pump / mixing pump, mixing hopper, mud tank and generator on the skid. The complete solids removal unit has been widely used for waste water treatment , we have standard compact design for convenient transportation and economic solution, also we can make customized design as per client’s requirement.